March 16th, 2024

Reinventing compliance in oil and gas

The critical role of BOP reliability and digital technologies

In the dynamic world of oil and gas extraction, ensuring compliance with industry standards is paramount. From environmental regulations to safety protocols, every aspect of operations must adhere to stringent guidelines to mitigate risks and maintain operational integrity.

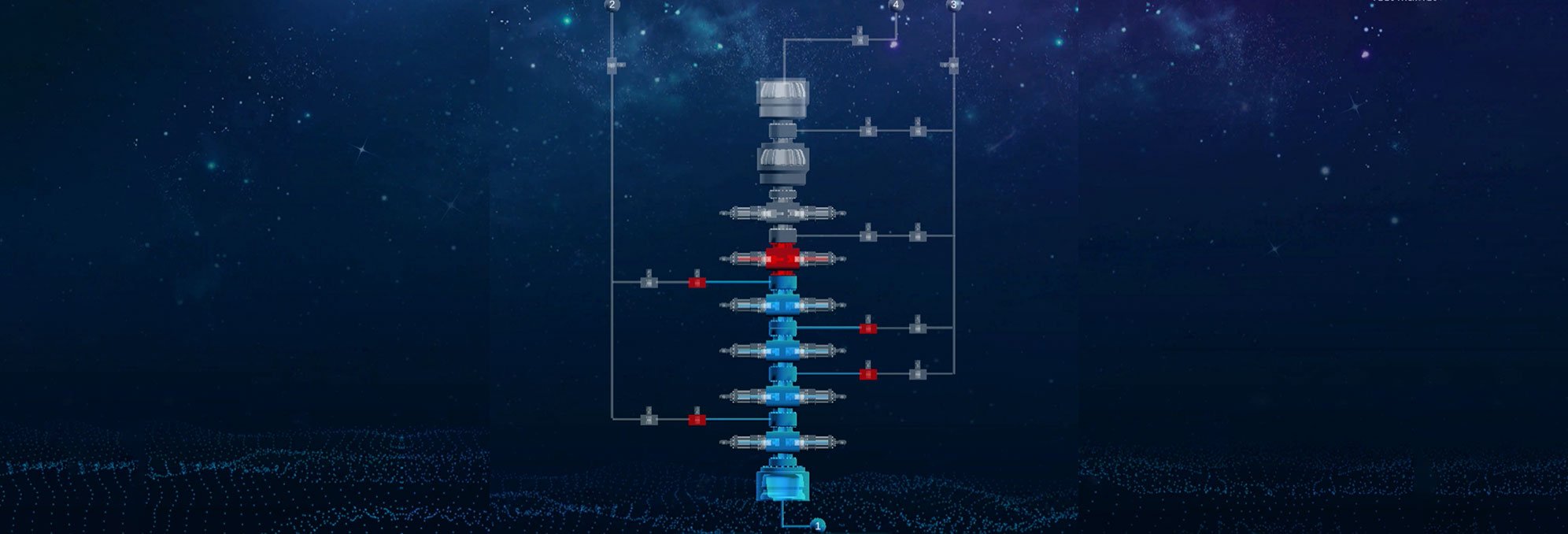

Among the crucial components in this ecosystem is the Blowout Preventer (BOP), a vital safety mechanism that prevents uncontrolled release of hydrocarbons during drilling operations.

Join our Newsletter to stay up to date on new Advancements, Announcements & more

Field Engineers

Custodians of BOP Reliability

Central to ensuring compliance assurance are the dedicated efforts of field engineers responsible for conducting routine inspections of BOP systems. These experts meticulously scrutinize each component, validating its integrity and functionality.

A crucial aspect of their role involves verifying the presence of essential documentation, such as relevant certificates like CoC's (Certificate of Conformance) and compliance records. This meticulous attention to detail not only showcases adherence to regulatory standards but also fosters confidence in the dependability of BOP systems.

BOP Real-Time Monitoring (RTM)

Proactive Compliance Management

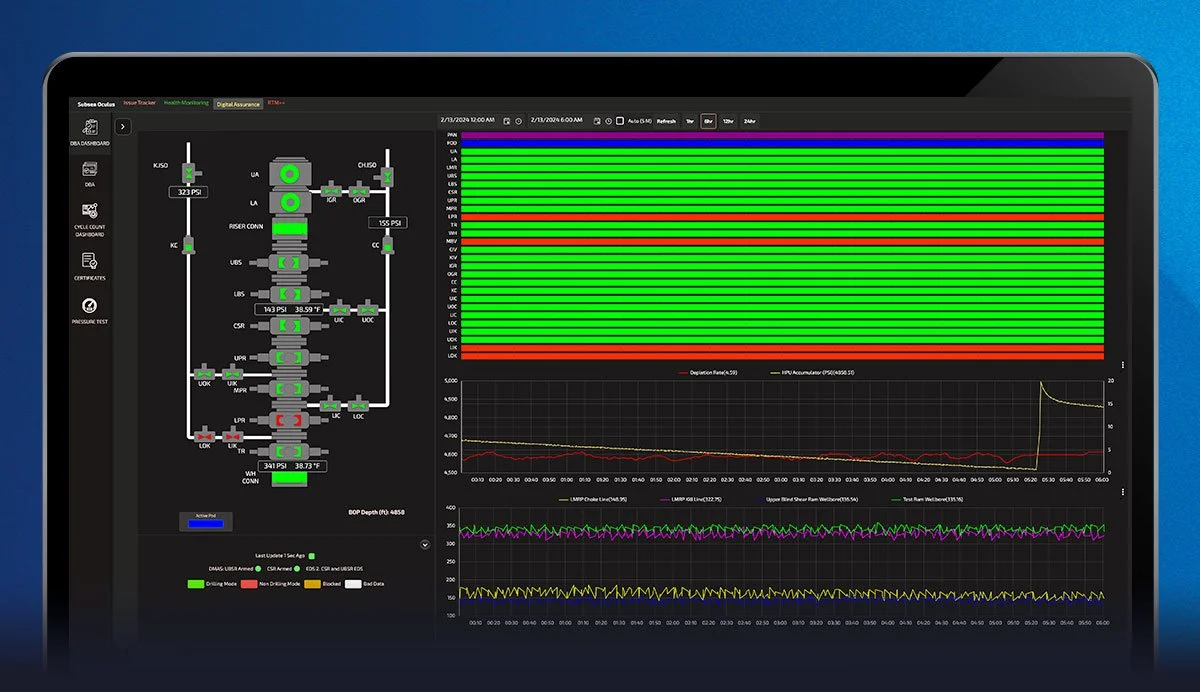

The oil and gas sector has undergone a transformative shift in compliance management, thanks to real-time monitoring capabilities.

Employing cutting-edge sensors and data analytics, operators can now consistently oversee BOP system performance parameters, promptly identifying anomalies and deviations in real-time.

This proactive BOP real-time monitoring (RTM) approach facilitates quick interventions in the event of non-compliance issues, effectively averting potential safety hazards and operational disruptions.

Digital BOP

Assurance (DBA)

Automating Compliance Checks

Digital BOP Assurance (DBA) tools integrate features such as compliance checks to streamline regulatory adherence.

For instance, compliance check features integrated into systems like API Standard 53 ensure that BOP operations align with prescribed guidelines such as gallon counts and timing.

This automated validation mechanism minimizes the risk of human error, ensuring alignment with regulatory standards for every aspect of BOP functionality. Integrating Digital BOP Assurance (DBA) tools into operations not only enhances compliance initiatives but also establishes and maintains a high standard of operational excellence.

Digital Pressure Testing (DPT)

Enhancing Accuracy and Efficiency

Digital Pressure Testing (DPT) provides a more precise and effective means of evaluating BOP performance. Through the digitization of the testing procedure, operators can access real-time data and insights, allowing them to proactively detect potential issues and promptly implement corrective actions.

This technology not only improves data accuracy but also enhances operational efficiency, reducing downtime and associated costs. Additionally, the innovation of automated compliance checks with API Standard 53 ensures the precision of compliance documentation in Digital Pressure Testing reports (First of its kind in industry).

This integration streamlines regulatory adherence, minimizes the risk of human error, and guarantees accuracy in compliance reporting, further enhancing the reliability and effectiveness of digital pressure testing in ensuring BOP compliance and operational integrity.

Embracing digital transformation in compliance management demands a strategic mindset. Operators need to commit to substantial investments in resilient infrastructure, comprehensive employee training, and robust cybersecurity measures. This strategic approach ensures the optimal utilization of digital solutions while effectively mitigating associated risks.

Conclusion

In summary, ensuring compliance in the oil and gas industry necessitates a holistic approach that combines human expertise with technological innovation.

The crucial responsibility of field engineers in preserving BOP reliability is enhanced by state-of-the-art tools like real-time monitoring and digital BOP assurance.

These advancements not only provide accurate data and automated validation but also enable proactive maintenance, significantly enhancing the impact of compliance efforts.

Embracing these forward-thinking solutions allows operators not just to fulfill regulatory requirements but also to improve operational efficiency and maintain high safety standards, contributing to a sustainable future in the industry.