BOP Real Time Monitoring Solutions

Be confident, knowing that world-leading BOP experts are monitoring your BOP, around the clock, in real-time.

The Heartbeat of Your BOP

The heartbeat of your BOP is the most important sound. Step into the future of BOP monitoring and increase your critical asset lifespan.

24/7 Real-time Monitoring

Support your well operations and Deepwater engineering team with 24/7 BOP real-time monitoring from some of the world’s most highly qualified surveillance engineers and BOP systems experts – giving you confidence that everything you do meets best practice.

Competence

With our guidance and support, there’s no more need to worry about poor internal training leading to inefficiency in operations due to lack of knowledge.

KEY FEATURES

24/7 Real-time operations center support.

KEY FEATURES

On demand fault tree system for system health status vs standards.

KEY FEATURES

Real-time displays.

KEY FEATURES

Trending reporting.

KEY FEATURES

Leak detection (BOP hydraulic system) analytics.

KEY FEATURES

Component failure prediction.

KEY FEATURES

Issue tracking database.

KEY FEATURES

In-between well maintenance optimization.

Issue Tracking & Maintenance Optimization

A custom-built system for wells teams to follow up on the status of observed issues and maintenance status.

Captures BOP failures, observations, OEM comms and tests history

Real-time tracking of maintenance tasks and Maintenance Optimization Analysis (MOA)

Digital Maintenance Map

Rig Documentation, Schematics, COC, COS, etc

NPT tracking

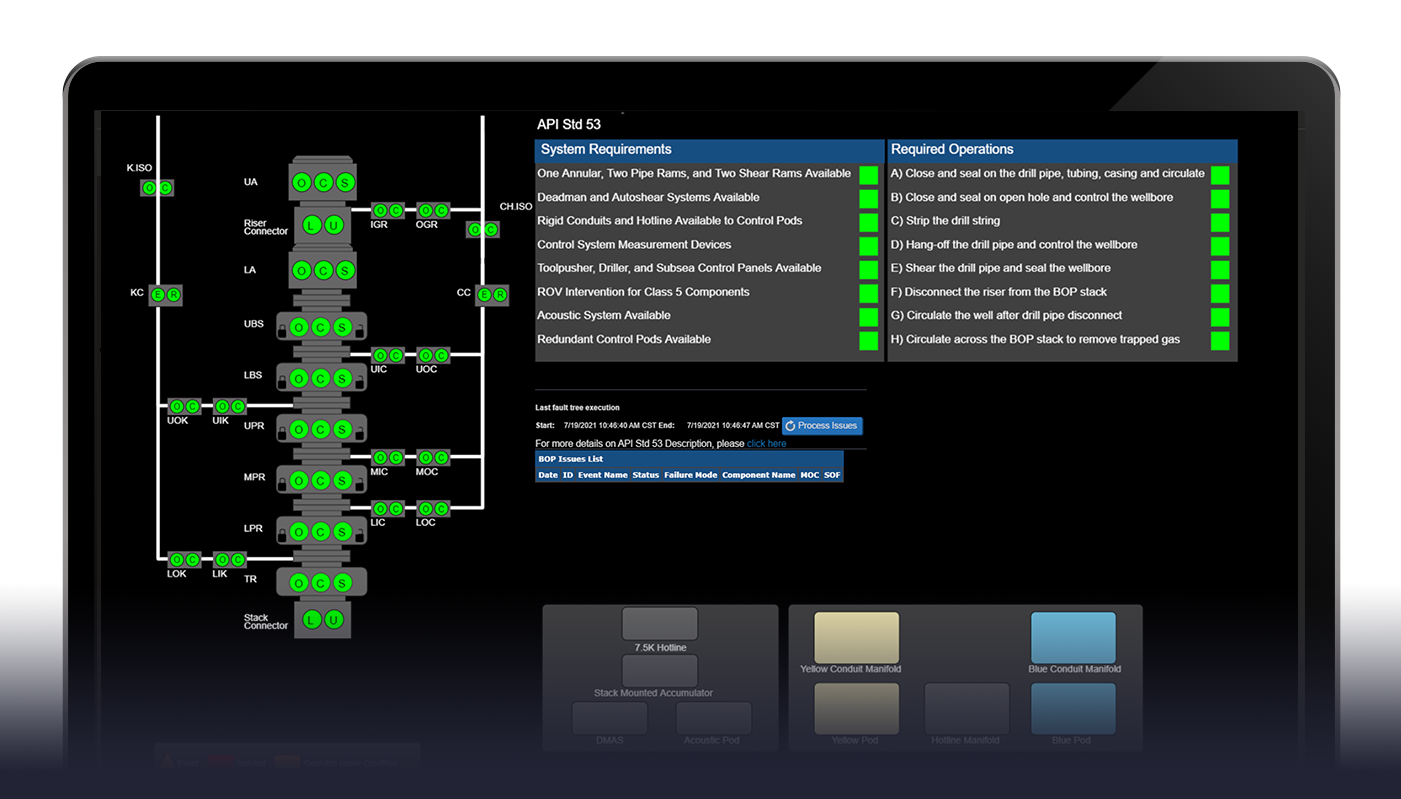

On Demand Fault Tree

Components-based fault trees are built to assess the effect of all the ongoing failures on the BOP availability and compliance.

7k+ BOP components modeled

Drilldown menus for each component function

Linked automatically to pending issues

Automatic reporting for regulatory submissions

RTM-DHW

Monitoring alarm/communications protocol of key well control parameters

Available 24/7 if the operator requires.

*US / GOM only - to meet the new regulatory requirement.