March 23rd, 2024

Crafting the future

Introducing Aquila Oculus

software platform

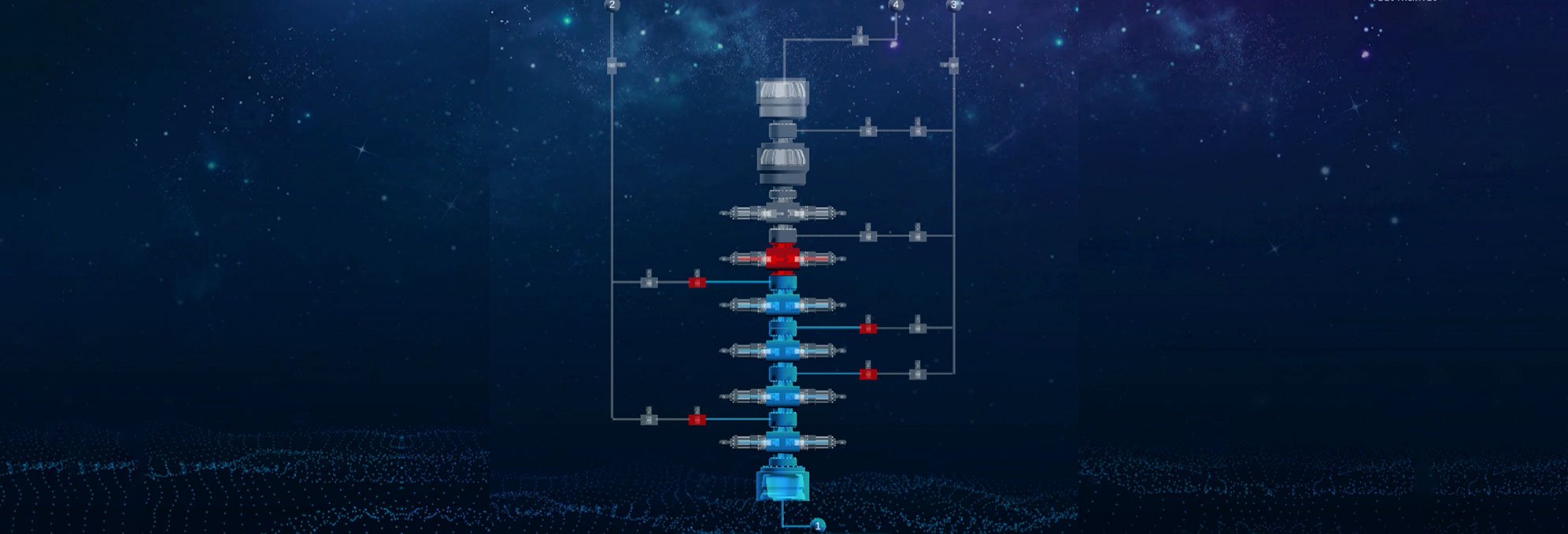

In the oil and gas sector, prioritizing the reliability and integrity of Blowout Preventers (BOPs) is crucial. BOPs act as a crucial safeguard against well blowouts, safeguarding both personnel and the environment. However, guaranteeing the dependability of BOPs goes beyond regular checks and maintenance; it necessitates thorough analysis and continuous monitoring.

Enter the Oculus software platform, a game-changer in BOP reliability management, leveraging advanced analytics and data-driven insights to revolutionize the approach to ensuring BOP reliability.

Join our newsletter to stay up to date on new advancements, announcements & more

Understanding BOP reliability

Ensuring the reliability of Blowout Preventers (BOPs), a critical aspect of well control, is paramount in the oil and gas industry. BOPs consist of intricate systems with various components designed to regulate well pressure and prevent the uncontrolled release of hydrocarbons. The repercussions of BOP malfunction or failure can be significant, underscoring the importance of continuous monitoring and proactive measures by operators.

Traditionally, BOP reliability management relied on manual inspections and periodic testing. While these approaches are indispensable, they may lack the precision required to detect underlying issues early on. Moreover, the substantial volume of data generated during BOP operations can overwhelm traditional analysis methods, posing a challenge in efficiently extracting meaningful insights.

Enter Oculus

The game-changer

in BOP reliability management

Oculus is not just another software platform; it represents a paradigm shift in BOP reliability management. By leveraging cutting-edge analytics and real-time monitoring capabilities, Oculus empowers operators to make data-driven decisions that enhance BOP safety and performance.

Real-time analytics

One of the key features of Oculus is its ability to provide real-time analytics of BOP behavior. By continuously monitoring parameters such as pressure, temperature, and hydraulic fluid flow, Oculus can detect anomalies and potential failures as they occur.

This proactive capability empowers operators to promptly implement corrective measures, thereby reducing the risk of BOP-related incidents.

Failure capture

and analysis

Oculus serves as a centralized repository for capturing and analyzing BOP failures and observations. Oculus establishes a valuable knowledge base to enhance BOP reliability progressively.

Additionally, the platform employs advanced machine learning algorithms to discern patterns and trends in the data, empowering operators to proactively address prevalent failure modes. This contributes to the overall improvement of BOP reliability through informed decision-making.

Testing history tracking

Maintaining a comprehensive record of BOP testing history is essential for ensuring compliance with regulatory requirements and industry standards.

Oculus streamlines this process by automatically documenting every BOP test performed, including the results and any deviations from expected performance.

This historical data provides operators with valuable insights into BOP health and enables them to track maintenance activities over time.

Enhancing BOP reliability: Unveiling the advantages of Oculus management

The implementation of Oculus offers numerous benefits for operators looking to enhance BOP reliability:

1. Improved Safety:

Improved Safety: By detecting potential failures in real-time, Oculus helps mitigate the risk of BOP-related incidents, ensuring the safety of personnel and the environment.

2. Enhanced Efficiency

Oculus' automated analysis and reporting functionalities optimize BOP reliability management processes, resulting in time and resource savings for operators, including the analysis of BOP testing times.

3. Data-Driven Decision Making

Oculus empowers operators to make informed decisions by leveraging comprehensive analytics and historical data, including fault tree analysis, which facilitates a deeper understanding of component failure and its impact on BOP reliability.

4. Continuous Improvement

By harnessing artificial intelligence algorithms, Oculus empowers operators to detect and remediate recurrent failure patterns, fostering ongoing improvements in BOP reliability over time.

5. Downhole Data Integration

Oculus' automated analysis and reporting functionalities not only streamline BOP reliability management processes but also offer the added capability of seamlessly switching to downhole data. This feature enables operators to access critical downhole information effortlessly, enhancing the overall effectiveness of BOP monitoring and maintenance activities.

Conclusion

In a Safety-Critical Industry, Advanced Analytics and Real-Time Monitoring (RTM) Take Center Stage for Unparalleled Reliability The Oculus software platform represents a significant advancement in BOP reliability management, offering operators the tools they need to proactively identify and address potential issues before they escalate. By harnessing the power of data-driven insights, Oculus is transforming the way BOPs are monitored, maintained, and managed, ensuring a safer and more reliable operating environment for all stakeholders.