Lessons from the Gulf: What We’ve Learned About BOP Reliability After +5 years Hours of Monitoring

June 4th, 2025

Insights from real-time data in the Gulf of America that are shaping the future of BOP performance and digital assurance.

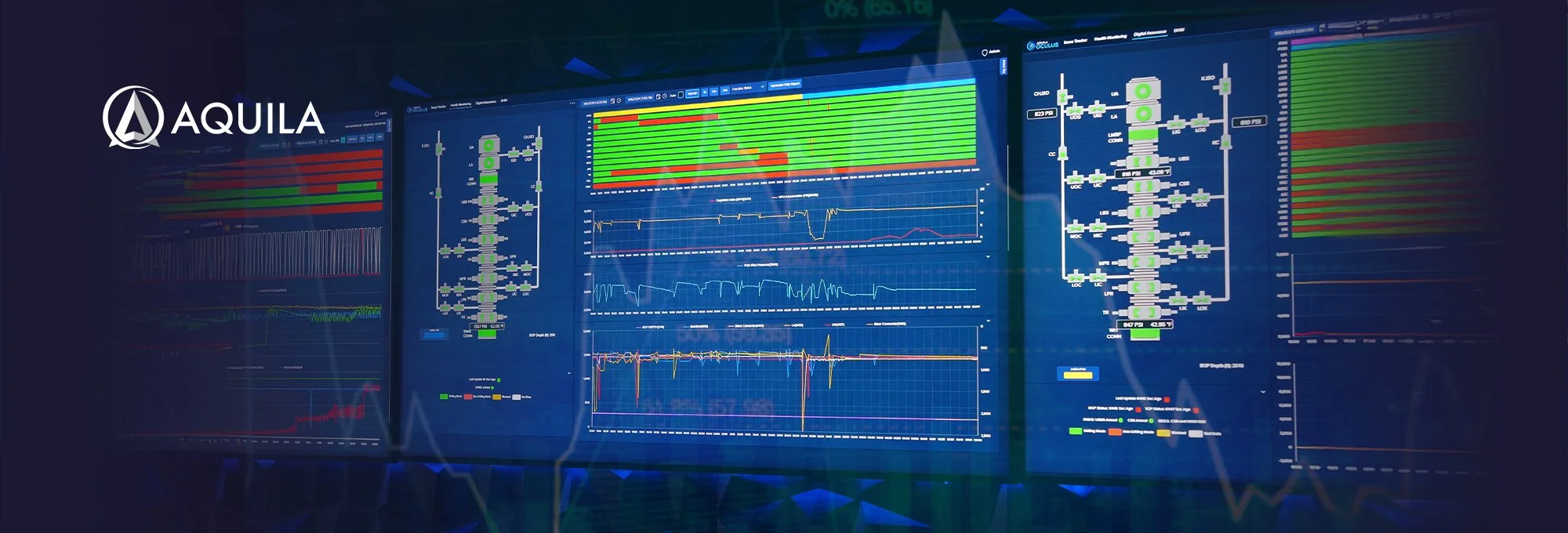

After more than five years of real-time monitoring Blowout Preventers (BOPs) in the Gulf of America, Aquila Engineering has gained unmatched insights into equipment reliability, testing efficiency, and engineering performance. This blog outlines the key lessons learned from years of digital BOP assurance—reinforcing our leadership among BOP testing companies and advancing how the industry approaches digital BOP testing services.

In this blog, we’ll dive into the critical takeaways from over a decade of monitoring BOPs in one of the world’s most active offshore drilling regions. These insights are built from robust BOP test data analysis, delivered through our custom-built real-time monitoring systems and digital BOP testing software. From improving operational efficiency to setting new benchmarks in remote digital pressure testing, the Gulf of America has served as both proving ground and innovation lab for BOP reliability.

1. Reliability Starts with Real-Time Visibility

The most significant driver of improved BOP reliability has been continuous visibility into equipment performance through real-time monitoring.

RTM drilling systems capture and analyze thousands of data points per hour, giving engineers immediate insights.

By using real-time monitoring systems, issues like valve response delays, pressure inconsistencies, or signal loss are detected early before they become operational problems.

Our findings show rigs using RTM experienced fewer test failures compared to rigs with manual-only processes.

This level of insight isn't just about speed; it's about enabling BOP engineers to make informed decisions using accurate, real-world BOP test data.

2. Not All Testing is Equal: Why Digital BOP Testing Outperforms Traditional Methods

When comparing traditional BOP testing with our digital BOP testing service, the gap in efficiency and clarity is undeniable.

Key advantages we’ve observed:

Digital BOP testing efficiency: On average, digital testing reduces test time without sacrificing quality.

Standardized and automated data capture reduces human error, with every pressure change and valve movement timestamped.

BOP tracking: With a complete digital trail, equipment history is easily auditable and compliant with regulatory demands.

Digital testing isn’t just more efficient, it empowers operators to shift from reactive to predictive maintenance, backed by structured, reliable BOP testing data analysis.

3. Data-Driven Engineering Decisions Reduce Downtime and Cost

We’ve seen firsthand how digitizing the BOP testing process leads to better decision-making at every level, from the rig floor to the engineering office.

Here’s what our analysis revealed:

Historical performance data identifies underperforming components before they fail.

Predictive analytics models based on millions of datapoints allow for proactive servicing strategies.

Collaboration between rig teams and onshore engineers is enhanced through centralized, accessible platforms for BOP testing software and test logs.

For BOP engineering teams, this is a game-changer: instead of chasing problems, they can design systems and procedures that prevent them.

Conclusion

After more than five years monitoring BOPs in the Gulf of America, the evidence is clear: digital transformation is no longer optional for operators serious about safety, uptime, and compliance. At Aquila Engineering, our work in digital BOP testing software, digital pressure testing, and BOP test data analysis has not only increased efficiency but reshaped how the industry defines BOP reliability. As we move forward, these lessons from the Gulf will continue guiding the next generation of BOP testing companies, engineers, and technologies.

If you’re ready to optimize your own operations with real-time, data-driven assurance, explore Aquila’s full suite of digital BOP solutions.