Boosting Offshore Reliability Through Digital Pressure Testing

August 13rd, 2025

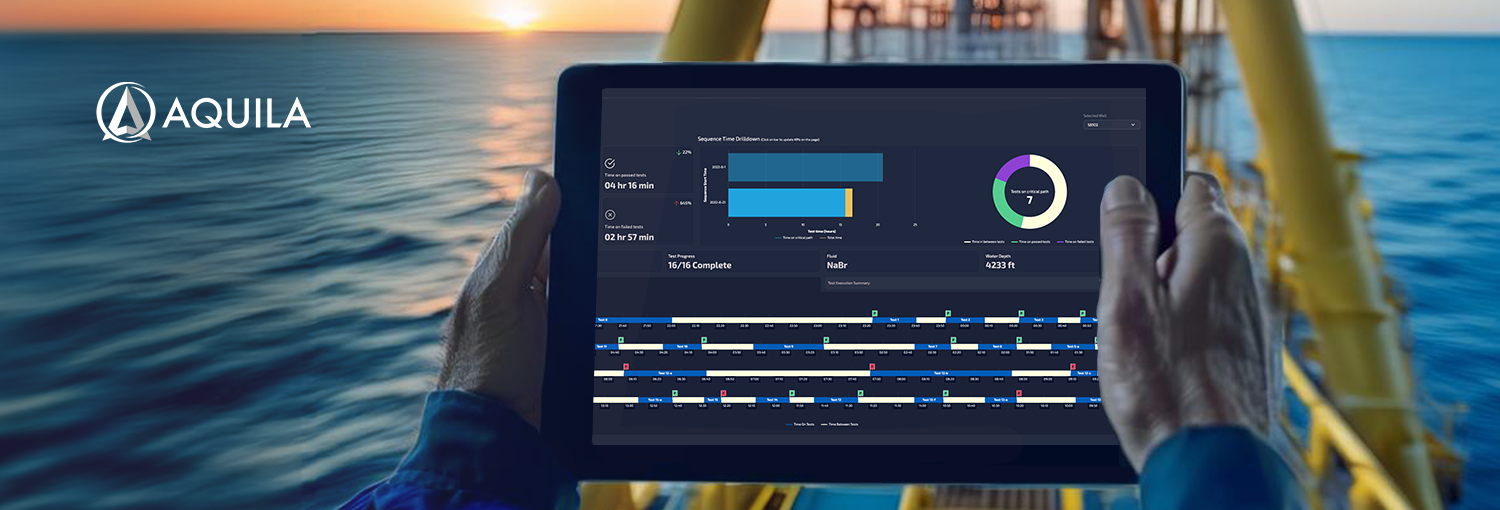

Why forward-thinking offshore operators are switching to digital BOP testing to improve safety, efficiency, and compliance.

As offshore operations grow more complex, ensuring the reliability of Blowout Preventer (BOP) systems has never been more critical. Traditional BOP pressure testing methods are not only time-consuming but can lead to inconsistent results and higher operational risks. In this blog, we explore how digital pressure testing for BOPs is revolutionizing offshore reliability through real-time data, remote monitoring, and intelligent analysis.

In this blog…

We’ll discuss how digital BOP testing increases operational efficiency, improves data accuracy, and supports API compliance — all while helping offshore operators cut costs. We’ll also explore key features of digital BOP testing software, explain how it enables real-time monitoring systems, and show how it transforms BOP test data analysis into actionable insights.

1. The Challenges of Traditional BOP Pressure Testing

While BOP testing is a regulatory requirement under API Standard 53 BOP testing, traditional methods introduce a number of inefficiencies and risks that compromise offshore reliability:

Manual Data Collection: Pressure readings taken with circular charts for pressure testing are prone to human error and difficult to interpret.

Lack of Real-Time Visibility: Without real-time monitoring, issues in the pressure test may go undetected until after completion.

Inconsistent Reporting: Inconsistent or missing documentation leads to potential non-compliance and reduced confidence in test validity.

Increased Downtime: Traditional BOP pressure testing often leads to extended non-productive time (NPT), costing operators thousands per hour.

By failing to evolve these methods, offshore operators risk operational inefficiencies, missed warning signs, and delayed decisions.

2. How Digital Pressure Testing Transforms Offshore Operations

Switching to digital BOP testing services it’s about unlocking real business and safety benefits. Here’s how digital testing boosts offshore reliability:

Real-Time Monitoring & Remote Access

Leverages real-time monitoring systems to track pressure levels during the test with high accuracy.

Enables remote digital pressure testing, allowing onshore experts to view results as they happen.

Supports RTM drilling operations by reducing the reliance on offshore-only data review.

Advanced Data Analysis & Reporting

Automatically records data for full BOP test data analysis.

Generates instant, auditable reports aligned with API Standard 53.

Supports BOP digital assurance by improving transparency and regulatory compliance.

Improved Efficiency & Reduced NPT

Cuts testing time by up to 40% with intelligent automation.

Reduces errors and retests through BOP pressure test procedure standardization.

Facilitates quicker decision-making with clean, structured digital BOP testing software outputs.

3. Choosing the Right Digital BOP Testing Solution

Must-Have Features:

Integration with well integrity software

Automated alerts and thresholds

Cloud-based test archiving and secure data access

Scalable architecture for multi-rig deployment

Compatibility with BOP tracking systems

Ideal For:

BOP engineers and operations supervisors needing clear, fast, and auditable results

BOP testing companies managing large fleets or requiring centralized oversight

Operators focused on lowering HSE risk and improving offshore execution

Whether you're conducting a routine BOP drawdown test, BOP pressure test, or full digital validation, the right software ensures every step meets global standards while supporting real-time collaboration.

Conclusion

Digital pressure testing for BOPs is no longer just a “nice to have” — it's a competitive necessity for offshore operators seeking greater reliability, safety, and operational control. With digital BOP testing software, teams gain access to real-time monitoring, streamlined workflows, and smarter insights that drive faster, better-informed decisions.

From reducing non-productive time to ensuring full compliance, the future of BOP testing is digital — and it’s already here.

Ready to move beyond the circular chart?